近年来,全球制造业加速向高端化转型,明泰铝业凭借近三十年铝加工领域的深厚积淀,坚定不移以技术创新重构产品价值,加速培育以创新、绿色、智慧、开放为主引擎的新动能。面对机器人、低空经济等新兴领域的需求,公司开发的全铝立柱机器人本体(立柱、大臂、小臂)、无人机屏蔽罩等新产品陆续供应市场。

In recent years, the global manufacturing industry has been accelerating its transformation towards high-end. With nearly three decades of profound accumulation in the aluminum processing field, Mingtai Aluminum Industry Co., Ltd. unswervingly reconstructs the product value through technological innovation and accelerates the cultivation of new driving forces mainly driven by innovation, greenness, intelligence and openness. In the face of the demands of emerging fields such as robotics and the low-altitude economy, the company's new products, such as the all-aluminum column robot body (column, large arm, small arm) and the UAV shielding cover, have been successively supplied to the market.

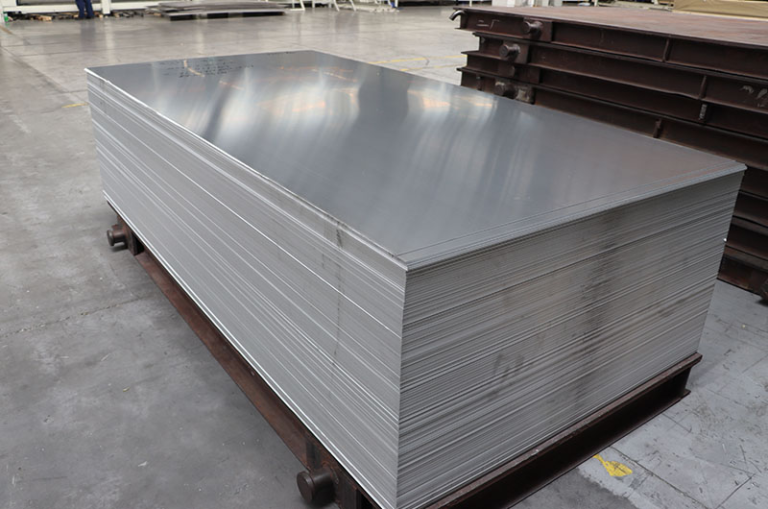

全资子公司鸿晟新材在建“汽车、绿色能源用铝产业园项目”,将投资建设铝板带生产用热处理设备气垫炉、辊底炉及化学表面处理线等高端设备,以技术突破构建核心竞争力,战略布局抢占未来赛道,积极打造第二增长曲线。

The wholly-owned subsidiary, Hongsheng New Materials, is constructing the "Aluminum Industrial Park Project for Automobiles and Green Energy." It will invest in building high-end equipment such as air cushion furnaces, roller hearth furnaces for heat treatment in the production of aluminum plates and strips, and chemical surface treatment lines. By achieving technological breakthroughs, it aims to build its core competitiveness, strategically lay out plans to seize the future development track, and actively create a second growth curve.

鸿晟新材项目

气垫炉采用气垫悬浮技术避免材料与炉体直接接触,显著提升铝板带箔的表面光洁度,通过精确控制加热速率、保温时间和冷却曲线,可实现铝材晶粒细化、消除内应力,优化材料的强度、延展性和耐腐蚀性,并可实现大规模连续化生产。辊底炉通过辊道传动实现连续热处理,精度控温,双室真空退火,有效防止高温氧化,可满足中厚铝板材不同合金的退火、固溶处理及大规模生产的场景需求。

The air cushion furnace employs air-cushion levitation technology to prevent direct contact between materials and the furnace body, significantly enhancing the surface finish of aluminum plates, strips, and foils. By precisely controlling the heating rate, holding time, and cooling curve, it can achieve grain refinement in aluminum materials, eliminate internal stress, and optimize the strength, ductility, and corrosion resistance of the material, while enabling large-scale continuous production. The roller hearth furnace realizes continuous heat treatment through roller table transmission, with precise temperature control and two-chamber vacuum annealing, effectively preventing high-temperature oxidation. It can meet the requirements for annealing, solution treatment, and large-scale production of different alloys in medium and thick aluminum plates.

化学表面处理线核心作用在于通过化学处理工艺提升铝材表面性能,采用三级清洗工艺,彻底去除自然氧化膜,通过阳极氧化工艺生成厚度可控的多孔氧化膜,显著提高铝材耐腐蚀性和耐磨性,为后续涂层或焊接提供清洁基底,满足车身外板的严苛使用环境,且适用于制造机器人、无人机等精密部件。

The core function of the chemical surface treatment line is to enhance the surface performance of aluminum materials through chemical processing. It adopts a three-stage cleaning process to thoroughly remove the natural oxide film, and generates a porous oxide film with controllable thickness via anodic oxidation. This significantly improves the corrosion and wear resistance of aluminum materials, provides a clean substrate for subsequent coating or welding, and meets the harsh service environments of automotive exterior panels. Additionally, it is suitable for manufacturing precision components such as robots and drones.

站在新质生产力发展的历史节点,鸿晟新材 “汽车、绿色能源用铝产业园项目”将打造先进制造标杆,聚焦机器人、低空经济、航天军工、新能源、汽车外板领域的市场需求,构建新兴产业生态,丰富高端产品线,加速明泰铝业向高端化转型升级,加速建设高端化、绿色化、数智化、精益化、国际化、服务化的全球领先的绿色铝加工企业。

At the historical juncture of new-quality productivity development, Hongsheng New Materials' "Aluminum Industrial Park Project for Automobiles and Green Energy" will establish a benchmark for advanced manufacturing. Focusing on market demands in robotics, low-altitude economy, aerospace and military, new energy, and automotive exterior panels, it aims to build an emerging industrial ecosystem, enrich high-end product lines, and accelerate Mingtai Aluminum Industry's transformation and upgrading towards high-end manufacturing. The project will also speed up the construction of a globally leading green aluminum processing enterprise that is high-end, green, digital and intelligent, lean, international, and service-oriented.